your location : Home

> Weidy Express > Weidy Monthly > Weidy Monthly Newsletter >

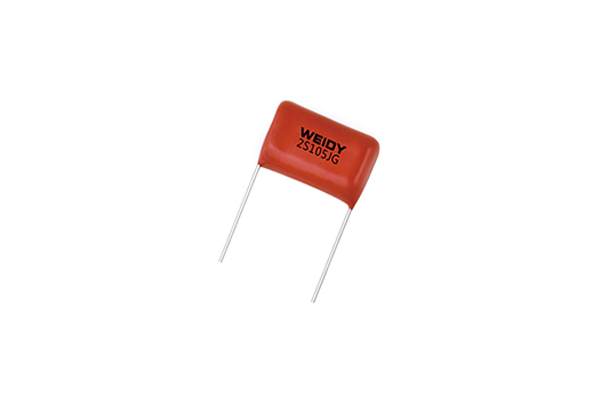

What is the difference between power electronic capacitors and filter capacitors?

2024-07-25 19:57:51

There are some differences between power electronic capacitors and filter capacitors in terms of application and performance. Here are the main differences between them:

1. Application fields:

Power electronic capacitors: Power electronic capacitors are mainly used in high-power applications such as DC filtering, pulse current applications, current resonance, etc. in power electronic equipment and systems. They are often used in fields such as AC power supplies, power inverters, power transmission and distribution systems, etc.

Power electronic capacitors: Power electronic capacitors usually have large capacitance and high voltage capabilities to meet the needs of high-power systems. Their capacitance can range from a few microfarads to thousands of microfarads, and the voltage level can reach several thousand volts.

Filter capacitors: The capacitance of filter capacitors is relatively small, usually between a few picofarads and a few millifarads, and the voltage level is usually between a few volts and a few hundred volts.

3. Frequency characteristics:

Power electronic capacitors: Power electronic capacitors usually have low ESR (equivalent series resistance) and ESL (equivalent series inductance) to adapt to high-frequency and high-power applications. They are able to withstand high current pulses and rapid voltage changes.

Filter capacitors: Filter capacitors operate in the low and medium frequency range, and their frequency characteristics are usually related to the cutoff frequency and frequency response of the filter.

4. Structure and materials:

Power electronic capacitors: Power electronic capacitors usually adopt structures such as aluminum electrolytic capacitors, electrolytic solid capacitors or metal film capacitors. They use highly conductive materials and special dielectrics to provide low ESR and high voltage capabilities.

Filter capacitors: Filter capacitors can adopt a variety of structures, such as multilayer ceramic capacitors (MLCC), polyester capacitors, polypropylene film capacitors, etc. These capacitors use different materials and structures to provide the required capacitance value and frequency characteristics.

In summary, power electronic capacitors are mainly used in high power applications, with large capacitance and high voltage capabilities, to meet the requirements of high frequency and high power. Filter capacitors are mainly used for filtering applications in signal processing and electronic circuits, with small capacitance, to meet the requirements of low and medium frequency ranges.

1. Application fields:

Power electronic capacitors: Power electronic capacitors are mainly used in high-power applications such as DC filtering, pulse current applications, current resonance, etc. in power electronic equipment and systems. They are often used in fields such as AC power supplies, power inverters, power transmission and distribution systems, etc.

Filter capacitors: Filter capacitors are mainly used for filtering applications in signal processing and electronic circuits, especially in DC power supplies and circuits for removing high-frequency noise and interference.

Power electronic capacitors: Power electronic capacitors usually have large capacitance and high voltage capabilities to meet the needs of high-power systems. Their capacitance can range from a few microfarads to thousands of microfarads, and the voltage level can reach several thousand volts.

Filter capacitors: The capacitance of filter capacitors is relatively small, usually between a few picofarads and a few millifarads, and the voltage level is usually between a few volts and a few hundred volts.

3. Frequency characteristics:

Power electronic capacitors: Power electronic capacitors usually have low ESR (equivalent series resistance) and ESL (equivalent series inductance) to adapt to high-frequency and high-power applications. They are able to withstand high current pulses and rapid voltage changes.

Filter capacitors: Filter capacitors operate in the low and medium frequency range, and their frequency characteristics are usually related to the cutoff frequency and frequency response of the filter.

4. Structure and materials:

Power electronic capacitors: Power electronic capacitors usually adopt structures such as aluminum electrolytic capacitors, electrolytic solid capacitors or metal film capacitors. They use highly conductive materials and special dielectrics to provide low ESR and high voltage capabilities.

Filter capacitors: Filter capacitors can adopt a variety of structures, such as multilayer ceramic capacitors (MLCC), polyester capacitors, polypropylene film capacitors, etc. These capacitors use different materials and structures to provide the required capacitance value and frequency characteristics.

In summary, power electronic capacitors are mainly used in high power applications, with large capacitance and high voltage capabilities, to meet the requirements of high frequency and high power. Filter capacitors are mainly used for filtering applications in signal processing and electronic circuits, with small capacitance, to meet the requirements of low and medium frequency ranges.

INDUSTRLAL electronic

INDUSTRLAL electronic

Scan code 5 seconds

Scan code 5 seconds